-

Product DescriptionCompany Info.<>

- Model:

- DN65-1200

- Material:

- DN65-1200

- Pipe diameter:

- ultra-high molecular weight polyethylene mm

- Pipe thickness:

- 65-1200 mm

- Service temperature range:

- 8-60 ℃

- Friction coefficient:

- -269 to +80

- Applicable fluid:

- Water pulverized coal, sewage discharge, pulverized coal, mineral powder, slurry

Shandong Dihao Wear Resistant Pipe Co., Ltd. is a company that produces UHMWPE pipe series products. UHMWPE pipe is a thermoplastic engineering plastic with excellent comprehensive performance in linear structure.It combines the superior properties of most plastics, impact resistance, low temperature resistance, wear resistance, chemical corrosion resistance, self-lubrication, and impact energy absorption. These six characteristics are currently high values in plastics.

The company is now producing ultra-high molecular weight polyethylene pipe specifications 65mm-1200mm, wall thickness 8 60mm, working pressure 1 - 3MPa of various specifications of ultra-high molecular weight polyethylene pipe. Ultra-high molecular polyethylene composite pipes can also be selected for working pressure above 2 3MPa. Ultra-high molecular weight polyethylene wear-resistant pipeline can be used for ore slurry transportation in mining industry, coal slurry transportation, underground filling in coal industry, coal ash and chemical water transportation in thermal power plant, corrosive medium, crude oil and natural gas transportation in chemical industry, sea lake salt chemical industry, urban water supply and drainage river dredging, etc. Ultra-high molecular weight polyethylene pipe characteristics:

1, ultra-high molecular weight polyethylene pipe impact resistance. High environmental stress resistance, cracking ability and scratch resistance, among which the impact strength is more than 10 times that of PE100 at normal temperature. The lower the environmental temperature, the stronger the impact resistance.

2, ultra-high molecular weight polyethylene pipe wear resistance is 4 to 7 times that of steel, polyethylene, polypropylene 10 times, PE is 2.3 times better for transporting fly ash small particle slurry.

Ultra-high molecular weight polyethylene pipe is a saturated molecular group structure, chemical properties are very stable, resistant to various corrosive media and organic solvents corrosion, more corrosion resistant than polyethylene, polypropylene, nylon, ABS and other plastics.

Ultra-high molecular weight polyethylene pipe has non-adhesion, its chemical and physical polarity is lower than ordinary plastics, scaling substances are also difficult to adhere. As long as the slurry velocity reaches 2.3~4.6 m/s, scaling is difficult to form. Even if the scale layer is slowly accumulated for a long time, it is not firm and easy to remove.

5, ultra-high molecular weight polyethylene pipe theoretical service life of up to several hundred years, ultra-high aging speed and embrittlement speed is very slow, buried in the ground for 50 years, its mechanical properties only dropped about 20%.

The friction coefficient of UHMWPE pipes is only 1/6 of that of new steel pipes, 1/5 of ordinary polyethylene, 1/20 of rubber, and 1/2 of polypropylene. Moreover, the ultra-high wear resistance and non-viscosity, corrosion resistance can always keep the pipe wall smooth and smooth, and the circulation capacity is generally higher than that of the steel pipe by more than 50%, so that the transmission system can maintain a low pressure and smooth state for a long time.

7, ultra-high molecular weight polyethylene pipe tensile yield strength and tensile fracture strength is higher, thermal deformation temperature is more than ten degrees higher than ordinary plastics, and cold brittle temperature almost no lower limit, coupled with 100% elongation, so, can be in a larger temperature range, withstand larger pipe stress, absorb impact load and shut down the occurrence of water pressure fluctuations.

8, ultra-high molecular weight polyethylene pipe welding process is simple, intuitive, high efficiency, weld strength exceeds the pipe body, for long distance pipes, especially medium and high pressure pipe installation provides convenience and guarantee. Super-high pipes do not need corrosion protection, the pipeline is light and soft, easy to handle and lay, allowing to change the trend according to terrain changes.

9, ultra-high molecular weight polyethylene pipe price is relatively moderate. The total engineering cost of medium diameter, medium and low pressure pipelines is even lower than that of seamless steel pipes, lower than composite pipes and alloy pipes, and the service life is more than 6 times higher than that of steel pipes and more than 4 times higher than that of composite pipes.

10, ultra-high molecular weight polyethylene pipeline is suitable for crude oil gathering pipeline, high pipe its advantages are light weight, easy installation and construction, low temperature resistance, anti-aging, so the crude oil gathering pipeline laying, its advantages are more prominent.

Shandong Di Hao wear pipe high quality UHMWPE pipe wholesale and retail, you only need a phone we will provide suitable products, welcome to call or visit the factory!

Business contact : Manager Wu

Tel:

Tel:

Dihao Website: www.dihaopipe.com

Address: No. 5005 Beiling Road, Free Trade Logistics Park, High-tech Zone, Zibo City, Shandong Province- Name(chinese)

- Name(English)

- Shandong Dihao Wear Resistant Pipeline Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Shandong Zibo, China

- Nearby port

- Qingdao

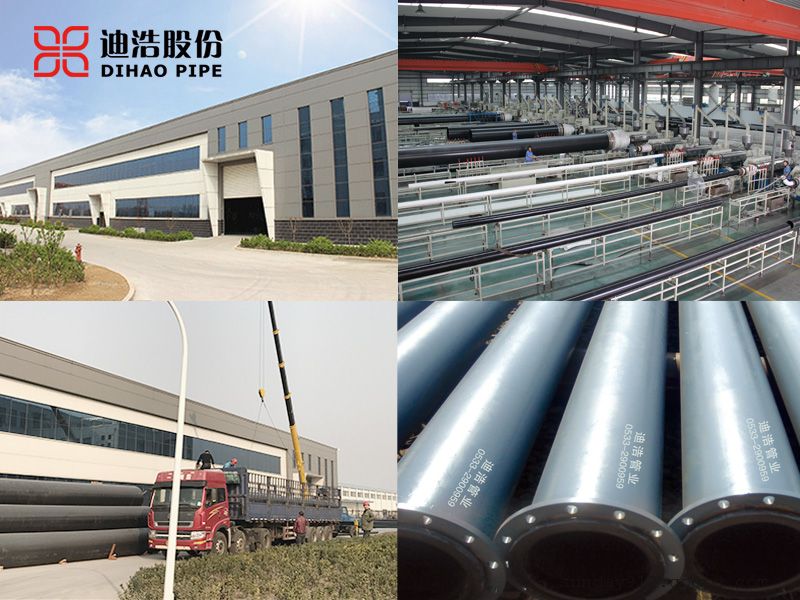

Shandong Dihao Wear Resistant Pipeline Co., Ltd. is headquartered in Zibo High-tech Zone, Shandong Province. It is a domestic joint-stock enterprise specializing in the research and development, production, sales and listing of ultra-high molecular weight polyethylene series products on the National Share Transfer System for Small and Medium-sized Enterprises (New Third Board). The company website: http://www.dihaopipe.com. The company is a state-recognized high-tech enterprise,"Ultra-High-tech Materials Industry Technology Innovation Strategic Alliance","Zibo City Ultra-High Molecular Weight Polyethylene Engineering Technology Research Center", an honest enterprise and advanced unit in Zibo City. Shandong Dihao Wear-resistant Pipeline Co., Ltd. has a registered capital of 42.42 million yuan and has a polymer material research and development laboratory building, a pipe production workshop and a pipe fitting processing workshop. There are more than 200 employees, of which 40.6% are scientific and technological personnel with college education or above and junior professional titles. They have standardized enterprise R & D institutions and strong innovative R & D and management teams. High-tech talents engaged in scientific research projects account for 14.58% of the total number of employees. There are 30 continuous extrusion production lines for ultra-high pipes, 20 production lines for diaphragm pipes, 22 sets of product testing and testing equipment, and an annual production and processing capacity of 20000 tons. The company's leading products include: ultra-high molecular weight polyethylene wear-resistant and corrosion-resistant pipes, ultra-high molecular weight polyethylene steel-plastic composite pipes, ultra-high molecular weight polyethylene pipes for underground coal mines, ultra-high molecular weight polyethylene steel skeleton composite pipes, ultra-high molecular weight polyethylene membrane composite pipes, ultra-high molecular weight polyethylene rollers and other ultra-high products. Pipe specifications cover various size below 1600mm in diameter. Ultra-high molecular weight polyethylene is a new polymer material and a strategic emerging industry encouraged by the state for development. The company has ultra-high molecular weight polyethylene pipe single screw extrusion technology, rich experience and high-quality products in the field of ultra-high molecular weight polyethylene pipes. It has obtained 6 invention patents and 12 utility model patents. "Professional and single-minded" has always been the goal pursued by Dihao people. Dihao brand ultra-high molecular weight polyethylene pipes have been used in major domestic metallurgical, mining, power, coal, chemical and other enterprises for many years and have been widely recognized. Shandong Dihao Company adheres to the path of "survival through quality, development through science and technology, and values contracts and promises". It strengthens management internally and improves independent innovation capabilities; externally, vigorously expands the market, strives to build the largest ultra-high molecular weight polyethylene pipe production base and R & D center in China, and strives to develop into the first domestic ultra-high pipe company listed on the GEM within 3-5 years. Dihao people are willing to work with friends from all walks of life to create a win-win situation for cooperation and jointly create a new era for the application of ultra-high pipes in the field of industrial transmission.- Name(chinese)

- Name(English)

- Shandong Dihao Wear Resistant Pipeline Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Shandong Zibo, China

- Nearby port

- Qingdao

Shandong Dihao Wear Resistant Pipeline Co., Ltd. is headquartered in Zibo High-tech Zone, Shandong Province. It is a domestic joint-stock enterprise specializing in the research and development, production, sales and listing of ultra-high molecular weight polyethylene series products on the National Share Transfer System for Small and Medium-sized Enterprises (New Third Board). The company website: http://www.dihaopipe.com. The company is a state-recognized high-tech enterprise,"Ultra-High-tech Materials Industry Technology Innovation Strategic Alliance","Zibo City Ultra-High Molecular Weight Polyethylene Engineering Technology Research Center", an honest enterprise and advanced unit in Zibo City. Shandong Dihao Wear-resistant Pipeline Co., Ltd. has a registered capital of 42.42 million yuan and has a polymer material research and development laboratory building, a pipe production workshop and a pipe fitting processing workshop. There are more than 200 employees, of which 40.6% are scientific and technological personnel with college education or above and junior professional titles. They have standardized enterprise R & D institutions and strong innovative R & D and management teams. High-tech talents engaged in scientific research projects account for 14.58% of the total number of employees. There are 30 continuous extrusion production lines for ultra-high pipes, 20 production lines for diaphragm pipes, 22 sets of product testing and testing equipment, and an annual production and processing capacity of 20000 tons. The company's leading products include: ultra-high molecular weight polyethylene wear-resistant and corrosion-resistant pipes, ultra-high molecular weight polyethylene steel-plastic composite pipes, ultra-high molecular weight polyethylene pipes for underground coal mines, ultra-high molecular weight polyethylene steel skeleton composite pipes, ultra-high molecular weight polyethylene membrane composite pipes, ultra-high molecular weight polyethylene rollers and other ultra-high products. Pipe specifications cover various size below 1600mm in diameter. Ultra-high molecular weight polyethylene is a new polymer material and a strategic emerging industry encouraged by the state for development. The company has ultra-high molecular weight polyethylene pipe single screw extrusion technology, rich experience and high-quality products in the field of ultra-high molecular weight polyethylene pipes. It has obtained 6 invention patents and 12 utility model patents. "Professional and single-minded" has always been the goal pursued by Dihao people. Dihao brand ultra-high molecular weight polyethylene pipes have been used in major domestic metallurgical, mining, power, coal, chemical and other enterprises for many years and have been widely recognized. Shandong Dihao Company adheres to the path of "survival through quality, development through science and technology, and values contracts and promises". It strengthens management internally and improves independent innovation capabilities; externally, vigorously expands the market, strives to build the largest ultra-high molecular weight polyethylene pipe production base and R & D center in China, and strives to develop into the first domestic ultra-high pipe company listed on the GEM within 3-5 years. Dihao people are willing to work with friends from all walks of life to create a win-win situation for cooperation and jointly create a new era for the application of ultra-high pipes in the field of industrial transmission. -

Send your message to this supplier*From:*To:

Mr. zhu

*Message:

Mr. zhu

*Message:

Copyright © 2003 - 2025 Goepe.com All rights reserved.